3D Printing in Medical Technology

Additive Manufacturing for Medical Equipment

3D Printing as an Efficient Alternative

Optimize Costs and Improve Products

Additive Manufacturing of Plastic Housings

Developed and Produced More Quickly, More Flexibly and Cost-Efficient

For laboratory equipment and medical imaging systems (also known as imaging diagnostics or just imaging, e.g. CT, MRT or X-ray equipment), additive manufacturing is a production technology that offers new opportunities to optimize both the product and the manufacturing costs.

Many medical devices and parts for laboratory equipment are complex niche products that are only produced in small series. Conventional production often requires expensive tools whose cost then needs to be added to the products. By contrast, additive manufacturing works without any tools, enabling parts to be manufactured in smaller series, right down to a batch size of one. The production process is based on the CAD data of the parts. This technology provides freedom of design, as well as the option to integrate functionality directly into the part. The results include shorter time-to-market and a wide range of opportunities for product optimization.

Find out more here about which laboratory equipment parts and diagnostic imaging equipment can already be optimized with EOS 3D printing today, and which machines and materials are right for your application.

- Tool-free production and reduced assembly costs

- Flexible design and functional integration

- Faster development cycles & time-to-market

EOS 3D Printing in Practice

Additive Manufacturing of Laboratory Equipment

3 Assembly Components Instead of 32 – the Washing Rotor by Hettich

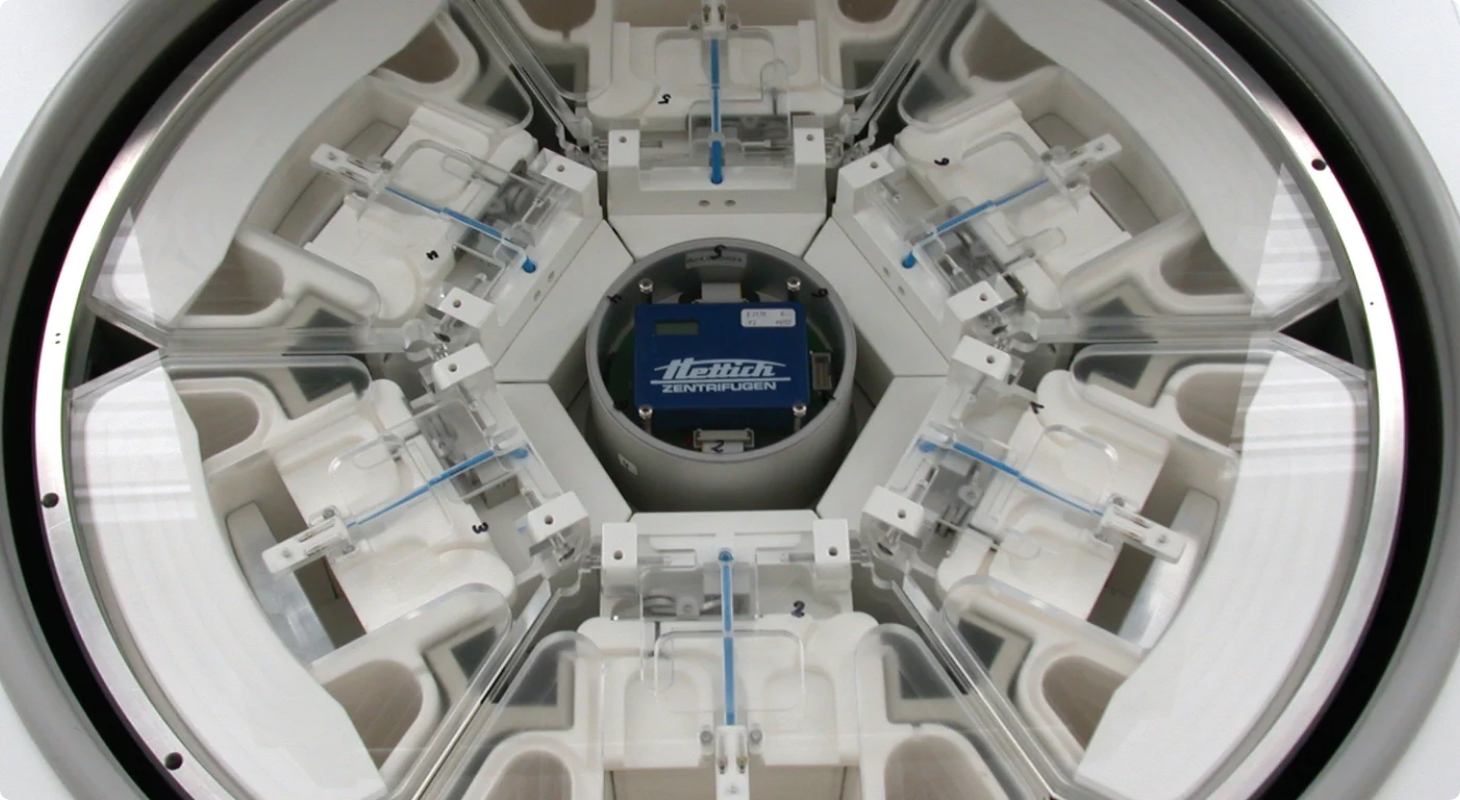

The centrifuge manufacturers Hettich significantly improved the cost-efficiency of their series production with additive manufacturing and are fully taking advantage of 3D printing. Hettich invented and patented a new type of centrifuge that allows blood components to be sedimented and separated in a single device.

The ROTOMAT consists of a drum motor with six containers and collection trays. The containers have an elaborate geometry and are placed under high rotational speeds, with accelerations of up to 1,200 times the acceleration due to gravity. Centrifuges use the centrifugal force to separate mixtures into their components. Typical applications include preparing blood samples or performing a blood panel. When manufactured conventionally, each washing rotor consists of 32 separate parts that need to be assembled. This requires complex tools and a time-consuming assembly process, especially since the stainless steel injectors need to be painstakingly deburred.

Switching to EOS technology paid off for Hettich – with outstanding numbers

- The washing rotor was redesigned and now consists of 3 assembly parts instead of 32 – with improved functionality.

- The containers are manufactured tool-free at lower production costs.

- Small series productions and regional adjustments can easily be implemented.

- Assembly no longer requires tools, and the time-consuming deburring step is completely eliminated.

Washing centrifuge for blood group serology manufactured with additive manufacturing technology from EOS

EOS 3D Printing in Practice Industrial 3D Printing for Parts for Medical Imaging Parts

Complex Structures, Delicate Details, Functional Integration

Additive manufacturing opens up a wide range of opportunities for medical imaging equipment. Highly complex, individual geometries can be implemented with the 3D printing process – including structures that would not be possible with conventional manufacturing. For example, parts for computed tomography or magnetic resonance tomography systems or X-ray equipment can be improved and manufactured more cost-efficiently.

Philips Incisive CT

EOS Case Study

3D Printer for Anti-Scatter Grids

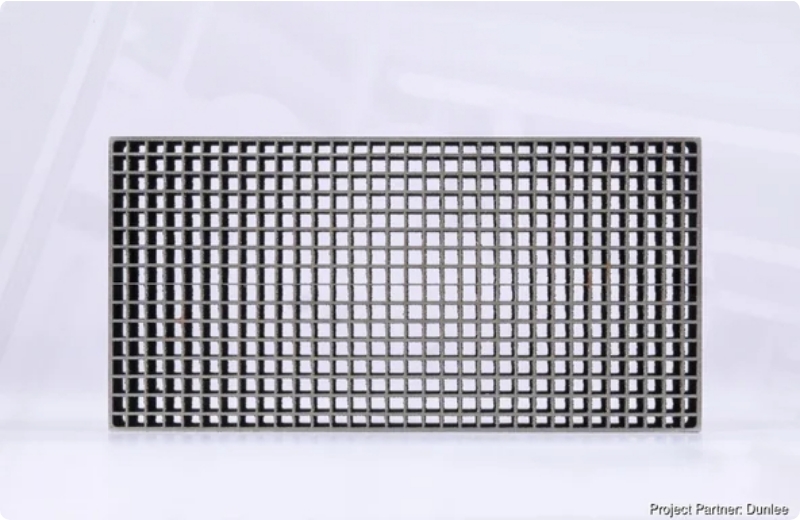

X-ray grids (anti-scatter grids) capture the X-rays deflected by the patient’s body tissue before they reach the film or imaging plate. This improves the contrast and accuracy of X-ray images. Making X-ray grids conventionally is extremely difficult and time-consuming, and therefore cost-intensive.

But 3D printing allows the sophisticated design to be manufactured according to a new and optimized approach. The EOS M 100 system combined with the EOS material Tungsten W1 is the first and only solution to the demanding challenge of manufacturing X-ray grids currently available on the market. It comes with a great advantage and has a more attractive cost per unit than manufacturing by conventional methods.

Anti-scatter grids from Dunlee