Industrial 3D Printing for a Perfect Fit

Digital Production of Orthoses and Prostheses

Additive Manufacturing of Plastic Housings

We offer systems, materials and processes, software, and services – anything that you need for the 3D printing of prostheses and orthoses. With our solutions, orthopedic technicians and companies benefit from reliable data, stable processes, and decades of market experience. Why 3D printing? With conventional manufacturing processes, the model needs to be manually adapted for each patient. The large number of steps involved means that production is expensive and time-consuming.

In terms of customization and cost-efficiency, conventional production methods like casting, molding, modeling and milling quickly reach their limits. Additive manufacturing offers maximum benefits for patients and manufacturers. The manufacturing process is based on individual scan data for each patient, meaning that 3D-printed prostheses and orthoses are optimally tailored to the anatomy and requirements of the wearer.

Orthoses and prostheses help their wearers to achieve better mobility. But every wearer has a different anatomy, usage and therapeutic needs. EOS 3D printing solutions successfully combine rapid manufacturing processes and optimal comfort for the wearer.

Medical parts in polymer powder bed when unpacking after 3D printing

Advantages of 3D Printing for Orthoses and Prostheses

- Virtually limitless customization potential in terms of design and functionality

- Optimal comfort for the wearer: lightweight and stable design despite complex structures

- Sustainable – less material consumption, since any leftover material can be reused

- Any necessary adjustments can be implemented quickly, for example with children who are still growing

- Increased comfort thanks to functional integration for more elasticity, breathable designs, etc.

- Fully digital process from scanning to the finished product, for faster availability

Innovation Story Mecuris

Manufacturing Prosthetic Feet on Demand

Mecuris offers a digital platform for patients, doctors, orthopedic workshops and medical suppliers. Using the data submitted to them, they provide contract manufacturing of 3D printed prostheses on EOS systems.

Customized prosthetic feet allow natural walking. The additive manufacturing process significantly reduces the lead time, achieves maximum comfort and enables customized design.

Play video

Paralympics Cyclist Denise Schindler

Optimal Prostheses Thanks to 3D Printing by EOS and Mecuris

Play video

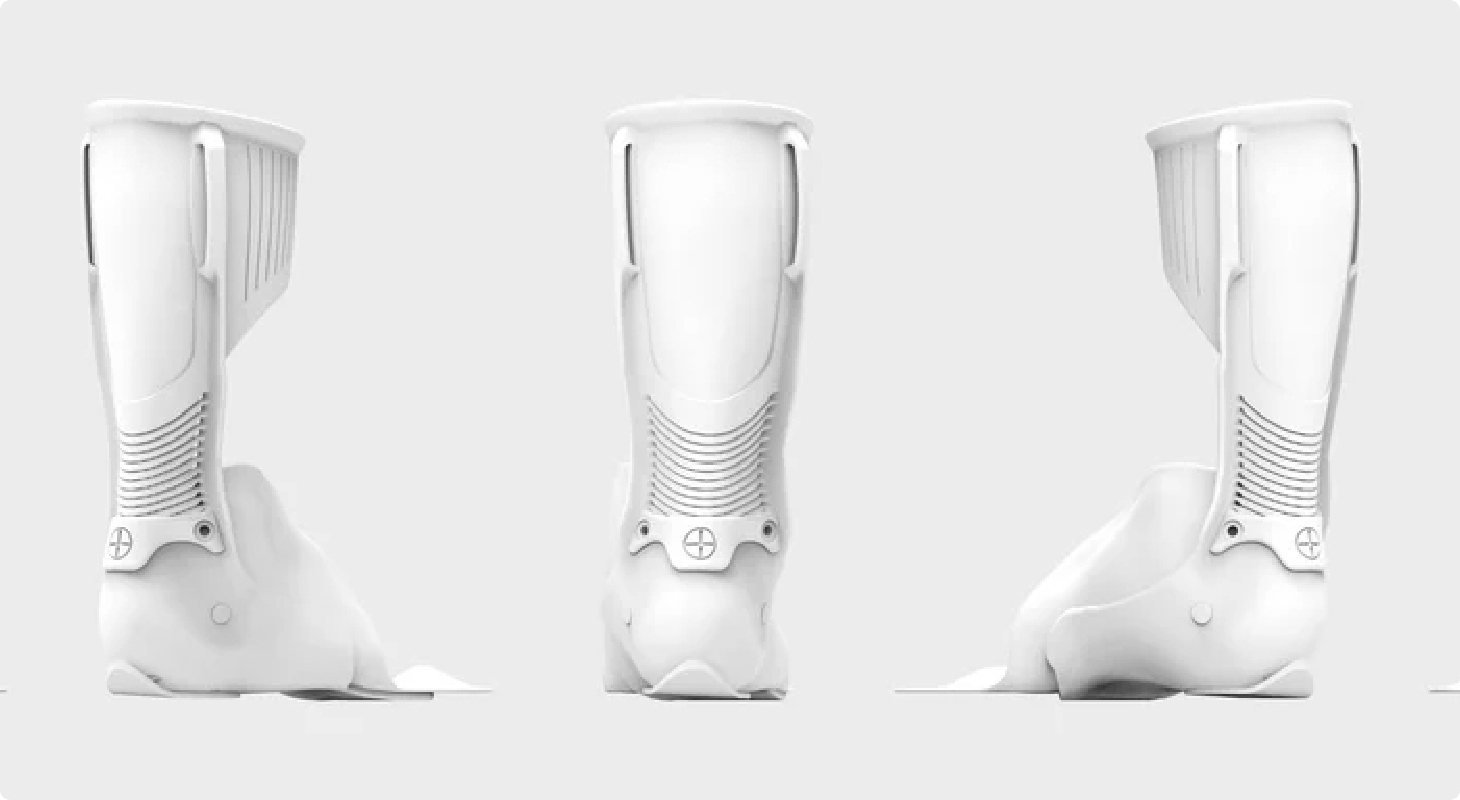

Innovation Story Ottobock

Series Production of Custom Foot Orthoses

Ottobock has been taking advantage of EOS technology to manufacture and sell orthoses since 2015. As the world’s first 3D printing service provider for orthopedic technology, the company works closely and successfully with orthopedic technicians to manufacture products on their behalf.

The result: the orthoses made by Ottobock feature a range of optimizations, for example in terms of weight, breathability, design and customization potential.

Ottobock Ankle-Foot-Ortheses

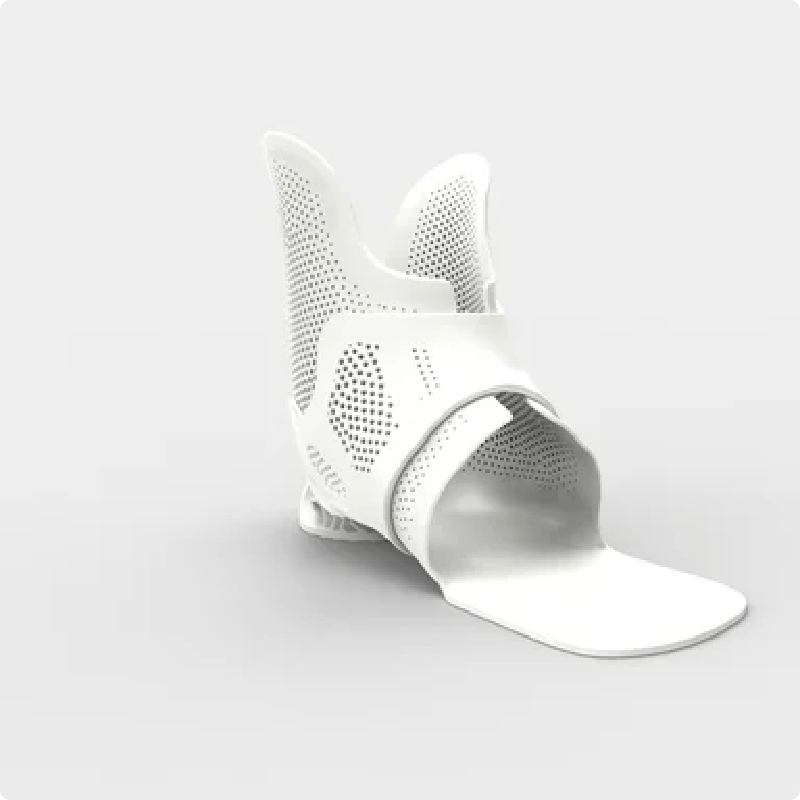

Innovation Story Andiamo

Perfectly Fitting Orthoses for Children

The British start-up company Andiamo uses EOS systems to make custom-fitting orthoses for children. Traditionally, orthoses are made from plaster impressions. This process is slow and resource-intensive and offers little room for customization.

Some patients, especially young patients who are still growing, have to undergo this procedure repeatedly. Waiting times can last up to six months – for an orthosis that might not even fit by the time it’s ready. Additive manufacturing reduces the waiting period to a minimum. Using a 3D body scan, a precise and perfectly fitting orthosis is manufactured and delivered within a week.

Additive manufacturing enables us to offer customized orthoses that are tailored to the individual needs of our patients. In addition, the design is breathable and very comfortable to wear.

Lukas Eckermann | Head of Patient Care and iFab (Individual Fabrication) | Ottobock