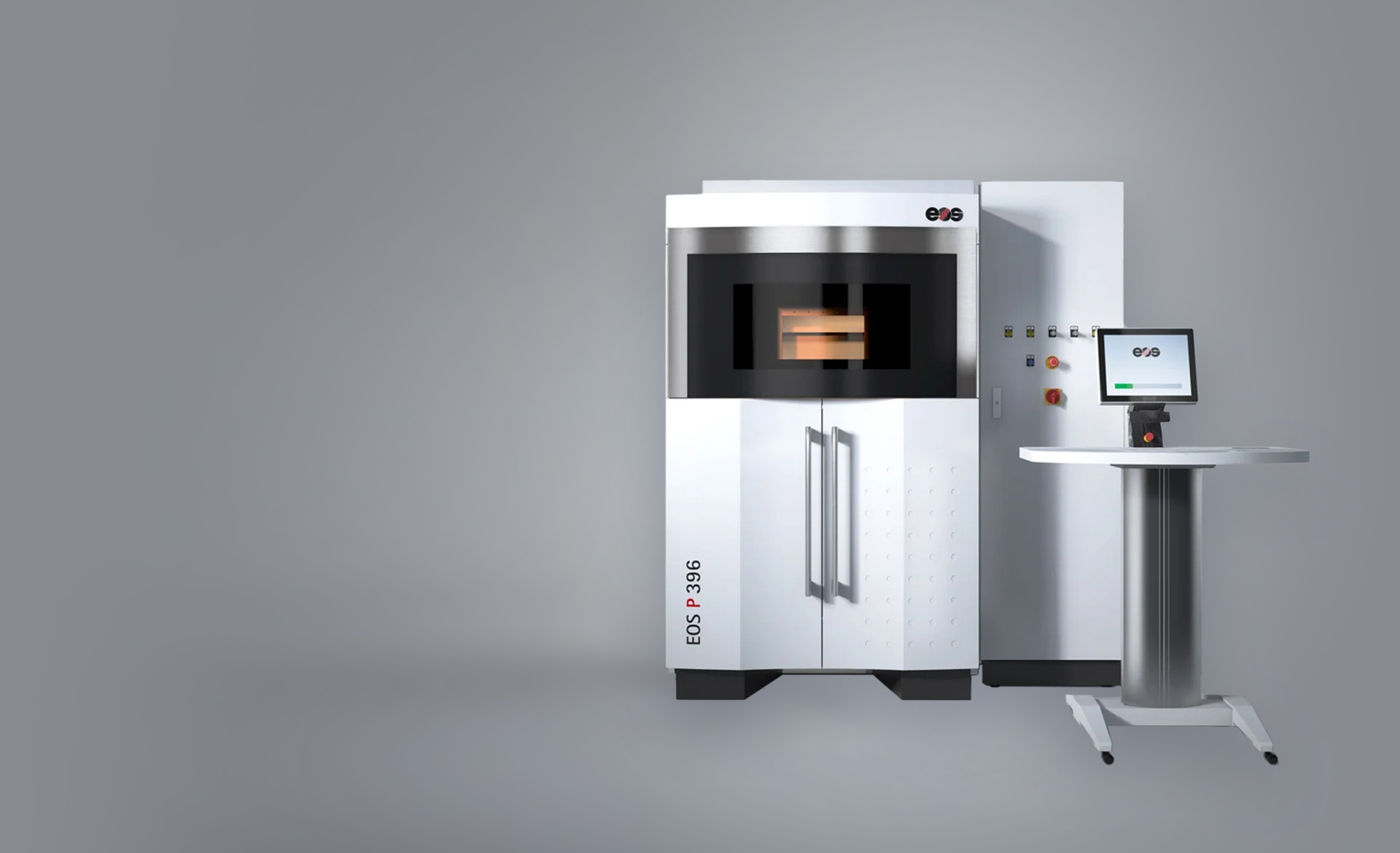

EOS P 396

Integratable into IIoT environments

Build rate of 3 l/h with a packing density of 5%

Widest portfolio of materials on the market

Most homogeneous part properties throughout the entire build volume

Diversity of Materials

14 materials and 26 parameter sets allow a wide range of applications. Requirements of various industries can be completely fulfilled.

Quality of parts

All 3D printed parts with excellent mechanical properties and dimensional accuracy due to software features such as Smart Scaling, EOSAME and a continuous temperature monitoring.

Connectivity

Full integration into the IIoT environment with EOSCONNECT Core resulting in an entirely digital process chain from the CAD model, through ERP and MES connection, to the finished part.

Technické údaje EOS P 396

- Construction Volume

- 340 x 340 x 600 mm (13.4 x 13.4 x 23.6 in)

- Laser Type

- CO₂, 70 W

- Precision Optics

- F-theta lens, high-speed scanner

- Scan Speed

- up to 6 m/s (19.7 ft/s)

- Power Supply

- 400 V / 32 A, max. power supply 16 A

- Power Consumption

- typical 2.1 kW; maximum 10 kW

- Machine Dimensions (W x D x H)

- 1,840 x 1,175 x 2,100 mm (72.4 x 46.3 x 82.7 in)

- Recommended Installation Space

- ca. 4.3 x 3.9 x 3.0 m (169.3 x 153.5 x 118.1 in)

- Weight

- ca. 1,060 kg (2,337 lb)

- Software

- PSW 3.8, EOSCONNECT Core, EOSCONNECT MachinePark,EOSCONNECT (open interface OPC-UA, Web API), Smart Scaling

Compatible materials

- PA 1101 - Polyamide 11

- PA 2200 - Polyamide 12

- TPU 1301 - Thermoplastic Elastomer

- PA 1102 Black - Polyamide 11

- HP 11-30 - Polyamide 11

- FR-106 - Polyamide 11

- PA 2201 – Polyamide 12

- PrimePart FR (PA 2241 FR) – Polyamide 12

- PA 2210 FR - Polyamide 12

- PA 3200 GF – Polyamide 12

- Alumide® – Polyamide 12

- PA 640-GSL – Polyamide 12

3D Printing in Practice

3D Printing in Practice

Additive Manufacturing in Motor Sports

Faster, lighter – and always safe: these are the requirements of motor sports development. For decades, EOS has been working with customers to exploit new potential using industrial 3D printing.

More information → Industrial 3D Printing for a Perfect Fit

Industrial 3D Printing for a Perfect Fit

Digital Production of Orthoses and Prostheses

We offer systems, materials and processes, software, and services – anything that you need for the 3D printing of prostheses and orthoses. With our solutions, orthopedic technicians and companies benefit from reliable data, stable processes, and decades of market experience.

Why 3D printing? With conventional manufacturing processes, the model needs to be manually adapted for each patient. The large number of steps involved means that production is expensive and time-consuming.

Industrial 3D Printing for Automation and Robotics

Industrial 3D Printing for Automation and Robotics

Additive Manufacturing for Handling Systems

Automation is moving forward, and all types of production and intralogistics processes are becoming increasingly networked thanks to digitalization. Robotics and gripping systems play a key role in this. But gripping technology in particular is constantly facing new challenges. Additive manufacturing makes it possible to address rapidly changing market trends in a targeted manner.

More information →