3D Printed Molds and Tools

Reduce Cycle Times, Increase Cost-Efficiency

Additive Manufacturing for Tooling and Mold-Making

3D printed molds and tools

Why using additive manufacturing to produce 3D printed molds and tools? As an industrial production method, the 3D printing process of additive manufacturing offers enormous design and manufacturing freedom. The most complex of shapes can be designed and produced in the highest quality, quickly and cost-efficiently, even for small batch sizes. In this way, the process provides a solution to a tooling challenge faced by many tool and mold makers:

In many industries, producing specialized tools and parts is one of the most resource-intensive manufacturing processes. Conventional processes are typically expensive, time-consuming and technically very challenging. The 3D printing process with EOS metal materials is the answer.

Audi Hotforming Toolinsert with conformal cooling channels and lightweight construction

Tooling

3D Printed Tools

Die Casting and Injection Molding with a 3D Printer

Our metal 3D printing solutions make it possible to integrate temperature control and cooling channels directly and conformally into your tools and tool inserts with DMLS technology. Conventionally, these channels can only be drilled in straight lines. However, with additive manufacturing, even highly complex shapes are not a problem, as the 3d printed tool is built layer by layer from CAD data. The heat can be dissipated much more evenly and quickly, and targeted cooling can be added around hotspots.

Why using Additive Manufacturing to Produce 3D Printed Tools?

- Production cycle times can be drastically reduced, and productivity is improved

- Increased quality and dimensional accuracy of parts, decreased rejection rate and unit costs

- Less tool warping, longer tool life

The Innovation for Your Manufacturing

LaserProFusion Technology for

Tool-Free Injection Molding

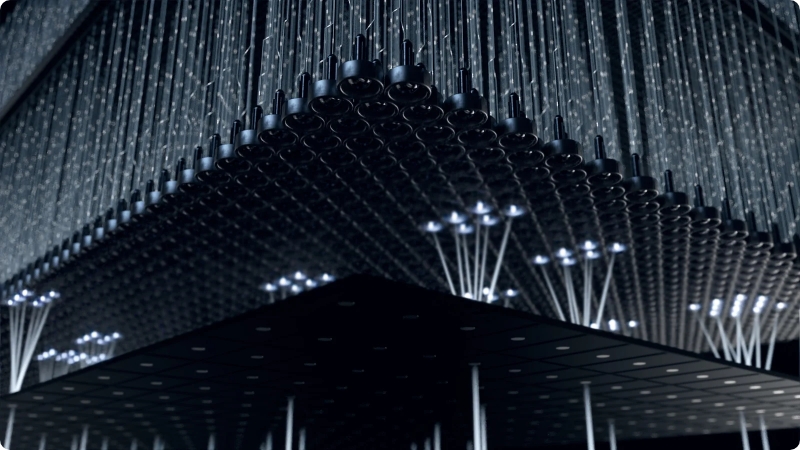

As productivity continues to improve, industrial 3D printing can be used not just for tools, but also for tool-free injection molding. With EOS LaserProFusion, we offer an extremely productive plastics technology that completely reinvents injection molding in many applications. The technology is founded on an array of around one million diode lasers. This opens up many completely new prospects for applications.

EOS LaserProFusion, 1 Mio Laser-Diodes

Mold-Making

3D Printed Molds

Outstanding Solutions for the Tire Industry

The ability to produce even the most complex structures in high quality and with short production times means that 3D printing also offers clear advantages for mold-making. The potential of the process truly shines when constructing tire segments, and the complex shapes that form the basis of the tread pattern.

Advantages of Industrial 3D Printing for Mold-Making

- Extremely complex structures are feasible

- Short production times guarantee significant time savings

- Efficient material usage, better cost-efficiency: instead of milling away large sections of material, the metal is only melted where necessary

Production with additive manufacturing has proven to be ideal. We successfully added conformal cooling channels to the tool insert. Heat is now dissipated much more quickly. As a result, the production cycle was reduced from 14 to 8 seconds, increasing monthly production by more than 56,000 units.

Arumugam Narayanaswami | Purchaser | Salcomp